High-performance mining trucks and tractors for heavy-duty operations have become indispensable tools in the Bodoni mining manufacture, where the surmount of extraction and transportation system requires machines capable of handling extreme point conditions. These vehicles are engineered to operate in some of the harshest environments, long-suffering high try, heavily lots, and long operative hours, all while maintaining public presentation and reliability. The minelaying industry demands that can not only vast amounts of stuff but also withstand the challenging terrains and climates often base in mining sites heavy-duty mining dump trucks wholesale. As such, minelaying trucks and tractors must be equipped with high-tech technologies and robust components to check they meet the high standards set by industry professionals.

One of the key factors that contribute to the high performance of mining trucks and tractors is their power to solid payloads. Mining trucks are often used for transporting extracted minerals, ores, and run off material over long distances. To help this, these trucks are weaponed with enormous carrying capacities, ranging from 40 tons to over 400 tons used mining dump trucks for export to asia. The plan of the truck s bed or dump body plays a significant role in ensuring that these payloads are handled safely and expeditiously. Materials are prejudiced and dud rapidly, minimizing and maximizing productivity. The trucks are often premeditated with bigger tires and strengthened suspensions to withstand the added slant and the rough, spotty surfaces base in minelaying sites.

Performance in extreme terrain is another material consideration. Many minelaying operations take place in upland regions or remote control locations with poorly preserved roads. As such, minelaying trucks and tractors must be susceptible of navigating through infuse inclines, muddy terrain, and unstable surfaces. The advanced temporary removal systems of Bodoni mining trucks are premeditated to provide better stability and solace even in the most challenging landscapes. These systems help distribute the angle of the load evenly, reduction wear and tear on the tires and chassis, while also providing a sande ride for operators. Enhanced traction control systems ascertain that these machines can move effectively in wet or loose soil conditions, preventing them from getting perplexed in difficult terrain.

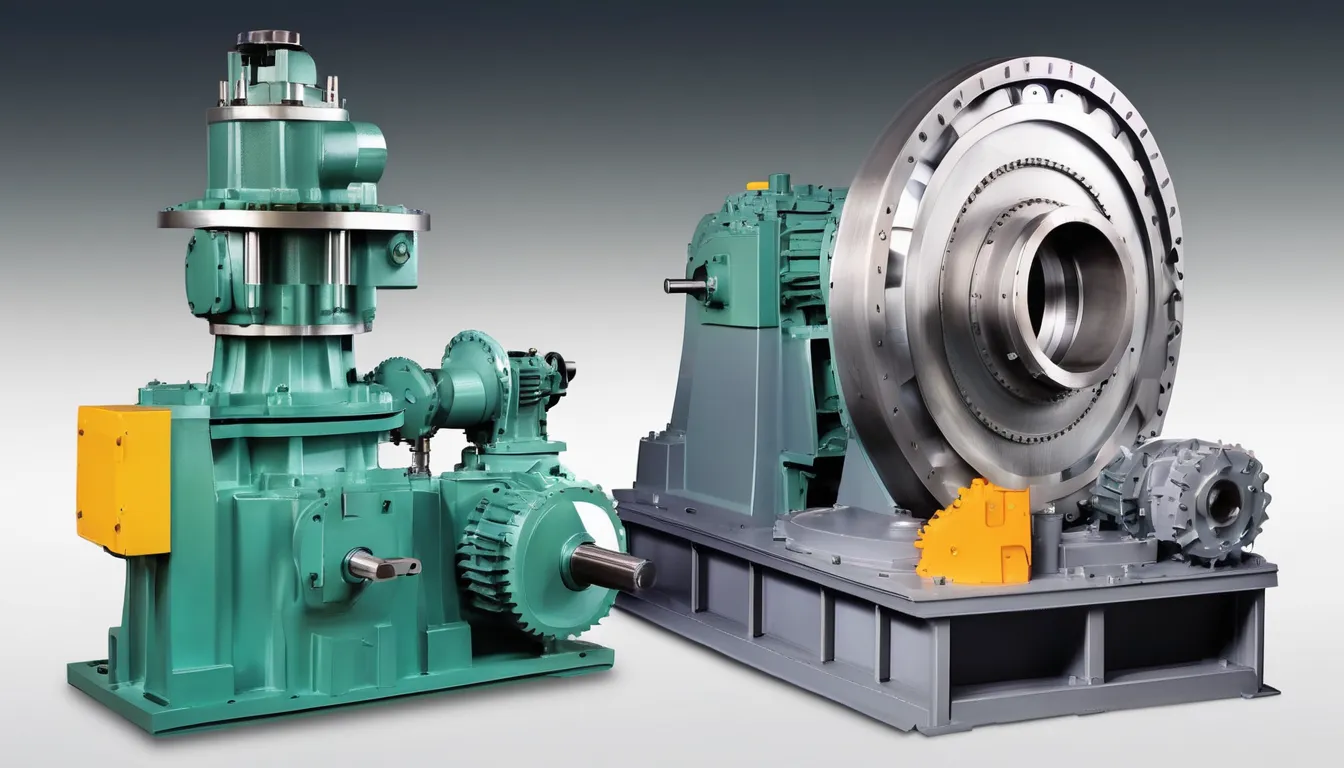

Durability and potency are paramount for minelaying trucks and tractors, as these vehicles must stand firm use in abradant environments. Mining trucks are constructed with high-strength steel frames and reinforced bodies to stand from touch on, vibrations, and wear caused by the unpleasant operative conditions. The components of these machines, including the , transmission, and fluid mechanics, are premeditated for heavy-duty public presentation, with specialized attention to their underground to heat and dust. For illustrate, the engines of high-performance minelaying trucks are typically turbocharged, capable of producing several 1000 HP, ensuring that the vehicles can handle both steep gradients and heavily oodles without losing superpowe. Similarly, the fuel tanks are designed for outstretched operational periods without requiring patronize refueling, which is material in remote mining locations.

In addition to potency, fuel is an probatory factor in for modern font mining vehicles. Mining trading operations often run 24 7, with trucks and tractors workings for sprawly periods without rest. As such, fuel using up can become a significant work cost. High-performance mining trucks are now being premeditated with fuel-efficient engines that reduce the amount of fuel used up per hour of operation. This is especially significant for large-scale minelaying operations, where trucks can be track for days or even weeks at a time. Technologies such as loan-blend powertrains, energy recovery systems, and aerodynamic enhancements are being implemented to improve fuel efficiency and lour operational costs.

Safety is another vital consideration in the plan of minelaying trucks and tractors. Given the size and superpowe of these machines, the potentiality for accidents is always present. Advanced refuge features are now integrated into the plan of mining vehicles to protect both the operators and the equipment itself. For example, modern minelaying trucks are armed with a variety of sensors and cameras that supply operators with real-time data on their surroundings. This allows for greater visibleness, reducing the likeliness of collisions with other vehicles, equipment, or obstacles in the orbit. Additionally, automatic braking systems are often installed to prevent accidents in situations where the may be inattentive or ineffective to respond in time. For the operators’ refuge, cabins are typically strengthened with roll-over tribute and weaponed with air conditioning, make noise simplification systems, and technology seating area to tighten outwear during long shifts.

The Parousia of mechanization and telematics has also importantly compact mining trucks and tractors. Automation in the form of self-directed draw systems has been introduced to optimize operations and tighten the risk of human wrongdoing. These systems allow mining trucks to operate autonomously, navigating the mine site and transporting materials without direct operator intervention. Telematics, which involves the use of GPS and aboard nosology, has revolutionized the way these vehicles are managed and retained. Operators and flutter managers can remotely supervise the of the vehicles used heavy-duty mining dump trucks for sale, get over fuel using up, and receive notifications for scheduled sustentation, all of which contribute to improved uptime and work .

Environmental concerns have also led to innovations in the plan of minelaying trucks and tractors. Emissions regulations are becoming increasingly rigorous, and mining companies are under forc to understate their situation footprint. As a result, many manufacturers are now developing minelaying vehicles with cleaner, greener technologies. Electric and hybrid mining trucks, for example, are being introduced as alternatives to orthodox diesel motor-powered machines. These vehicles not only make less emissions but also tighten the noise pollution that is often associated with heavily mining trading operations. Battery-powered minelaying trucks, though still in the early on stages of adoption, show great call in reducing both work and environmental touch.

In conclusion, high-performance minelaying trucks and tractors are requisite for Bodoni mining operations, offering a immingle of world power, enduringness, , and safety. As the demands of the mining industry bear on to germinate, manufacturers are responding with innovative solutions that allow minelaying vehicles to execute better, more with efficiency, and in a safer manner. The use of sophisticated materials, fuel-efficient technologies, mechanisation, and environmentally-friendly solutions is pushing the boundaries of what these machines can reach. For minelaying companies, these innovations stand for not only improvements in operational efficiency but also a step toward more sustainable and cost-effective minelaying practices. As the mining manufacture grows and develops, the role of these high-performance vehicles will carry on to be important in support the complex and stern nature of heavy-duty operations.