When you’re sourcing from industrial gearbox manufacturers, you need to approach the process with a strategic mindset. It’s not just about picking a gearbox; it’s about understanding the various types that align with your specific application needs. You’ll want to consider crucial specifications like torque capacity and gear ratio, but that’s only the beginning. Evaluating the credentials of potential manufacturers is equally vital. So, how do you ensure you’re making the right choices that lead to long-term efficiency? Let’s explore the key factors that can make or break your sourcing decision.

Understanding Gearbox Types

When you dive into the world of industrial gearboxes, it’s essential to understand the various types available. Gearboxes play a crucial role in transferring power and controlling speed in machinery, so knowing your options can significantly impact your project’s success.

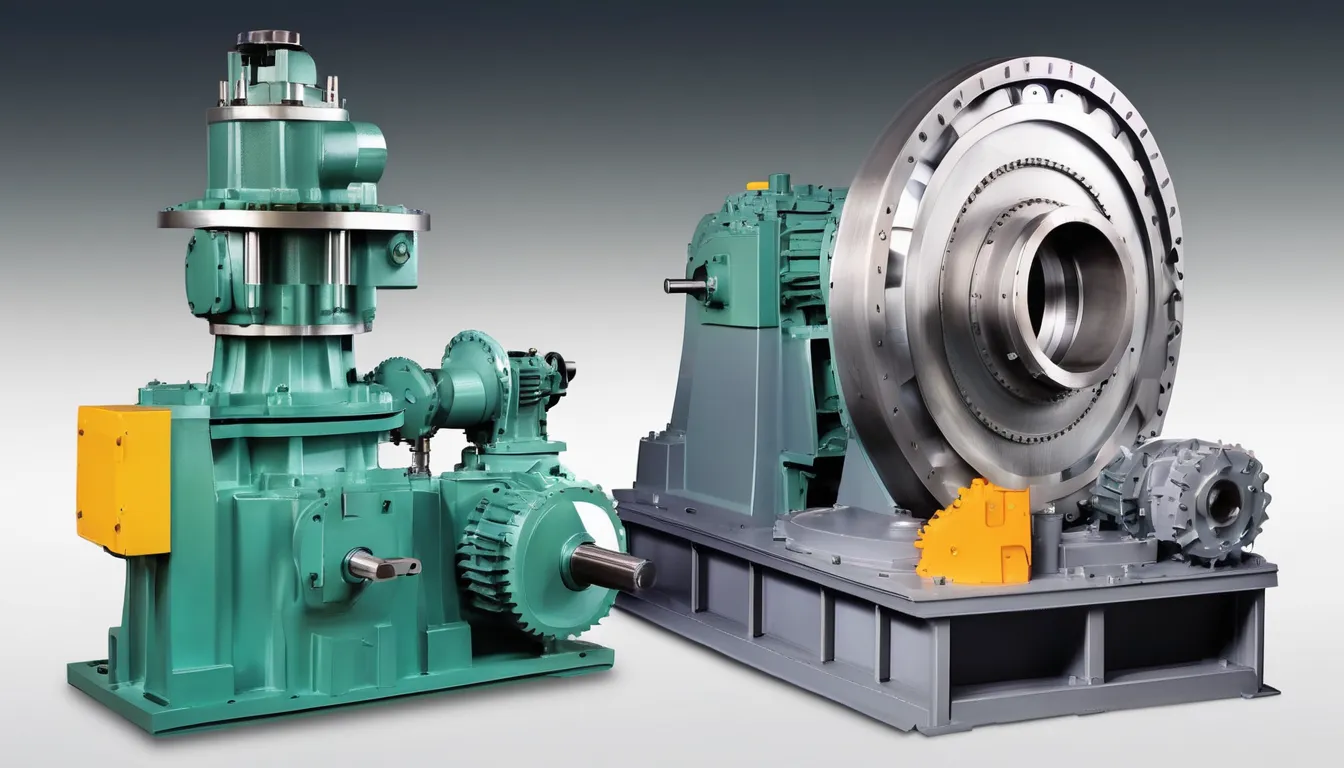

You’ll encounter several common types, including helical, bevel, worm, and planetary industrial gearbox manufacturer es. Helical gearboxes are favored for their efficiency and quiet operation, making them ideal for applications where noise reduction is key.

Bevel gearboxes, on the other hand, are designed to change the direction of rotation, which is useful in tight spaces. Worm gearboxes offer high torque output with a compact design, perfect for situations requiring significant reduction ratios.

Lastly, planetary gearboxes are known for their robustness and ability to handle high loads, making them a go-to for heavy-duty applications.

Each type has its unique advantages depending on factors like load requirements and operational conditions. By familiarizing yourself with these gearbox types, you can make informed decisions that align with your specific needs and improve the efficiency of your machinery.

Key Specifications to Consider

Understanding key specifications is crucial in selecting the right industrial gearbox for your needs. By focusing on important factors, you can ensure optimal performance and longevity of your machinery.

Here are three key specifications to consider:

- Torque Capacity: This indicates the maximum torque the gearbox can handle. You’ll want to ensure it meets or exceeds the demands of your application to prevent failure.

- Gear Ratio: The gear ratio affects the speed and torque output. It’s essential to choose a ratio that aligns with your operational requirements, balancing speed and power effectively.

- Efficiency: Gearbox efficiency influences energy consumption and operational costs. Look for gearboxes with high efficiency ratings to reduce energy waste and improve overall performance.

Evaluating Manufacturer Credentials

Selecting the right industrial gearbox doesn’t just stop at understanding its specifications; evaluating the manufacturer’s credentials is equally important. You want to ensure you’re partnering with a reliable and reputable manufacturer who meets industry standards.

Start by checking their certifications—ISO standards, for instance, can indicate a commitment to quality and consistency. Look into their experience in the industry; manufacturers with years of expertise are often more reliable. Customer reviews and testimonials can also provide insights into their service and product reliability.

Here’s a quick reference to help you evaluate manufacturers:

| Credential Type | Importance | How to Verify |

|---|---|---|

| Certifications | Ensures quality and compliance | Check their official website |

| Industry Experience | Indicates reliability and expertise | Review company history |

| Customer Feedback | Reflects satisfaction and trust | Look for reviews on third-party sites |

| Warranty and Support | Shows commitment to service | Inquire about terms and conditions |

Comparing Pricing and Value

Finding the right balance between pricing and value is crucial in your search for industrial gearboxes. You don’t want to compromise quality for a lower price, nor do you want to pay a premium without understanding the benefits.

To navigate this effectively, consider the following:

- Total Cost of Ownership: Analyze not just the upfront cost but also the long-term expenses. Maintenance, energy efficiency, and lifespan can significantly impact your overall investment.

- Performance Metrics: Assess how the gearbox’s specifications align with your operational requirements. A slightly higher-priced option might offer better reliability and efficiency, ultimately saving you money on repairs and downtime.

- Manufacturer Reputation: Research the manufacturer’s track record. A company known for high-quality products might charge more, but their gearboxes often come with better warranties and customer support, providing additional value.

Building a Long-Term Partnership

Building a long-term partnership with your industrial gearbox manufacturer can significantly enhance your operational efficiency and reliability. When you establish a strong relationship, you gain access to their expertise and resources, ensuring you receive tailored solutions that meet your specific needs.

Start by communicating openly about your requirements, goals, and any challenges you face. This transparency fosters trust and encourages collaboration. Regularly engaging in discussions about product performance and potential improvements can lead to innovations that benefit both parties.

Don’t shy away from providing feedback. Constructive criticism helps your manufacturer understand your expectations and refine their offerings. In return, be willing to listen to their insights; they often have valuable knowledge about industry trends and best practices.

Consider investing in joint training sessions to better understand each other’s processes. This can enhance your team’s skills while deepening your relationship.

Lastly, be patient. Building a partnership takes time, but the rewards are worth it. A reliable manufacturer won’t only support your current needs but will adapt to future changes, ensuring your operations run smoothly for years to come.

Conclusion

When sourcing from industrial gearbox manufacturers, remember to prioritize your application needs, evaluate key specifications, and vet manufacturers thoroughly. Don’t just focus on price; consider the overall value and total cost of ownership. By building strong partnerships with reliable suppliers, you’ll enhance your machinery’s efficiency and performance. Stay informed and make decisions that align with your operational goals, ensuring you get the best gearbox solution for your unique requirements.